Carbon Steel Hardness Brinell

1 Hardness Conversion Calculator for metals according to ASTM E140 - 12Standard Hardness Conversion Tables for Metals Relationship Among Brinell Hardness Vickers Hardness Rockwell Hardness Superficial Hardness Knoop Hardness Scleroscope Hardness and Leeb Hardness. Values based on Brinell 10mm Standard Ball 3000kgf.

What Is Low Carbon Steel Definition Material Properties

Steel hardness conversion chart all values approximate.

. Cold working AISI 1018 carbon steel will affect the hardness and mechanical properties. Brinell Rock well hardness. 15 Conversion Table 5 presents data on the relationship between Brinell hardness and Rockwell B hardness of auste-nitic stainless steel plate in the annealed condition.

Among Brinell hardness Vickers hardness Rockwell hardness and Rockwell superficial hardness of cartridge brass. Alloy Pipe and Products. Mangalloy is heat treatable.

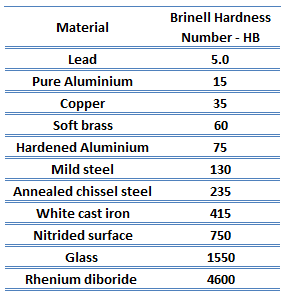

Elongation at Break Percentage. Typical hardnesses of 1095 carbon steel after tempering for 2 hours at different temperatures. Brinell hardness of high-carbon steel is approximately 200 MPa.

Rockwell Superficial Brinell Vickers Shore Hardness Conversion Chart. ASTM A515 Gr 70 Plates. AISI 1095 is high carbon steel with high hardness and wear resistance usually used to make various daggers and knives.

Also known as mild steel it is a low-cost material that is easy to shape. It is exceptionally easily to weld and has good machinability properties. Brinell Rockwell Hardness Conversion.

Carbon Steel Cast Steel Hardness Conversion. The Hardness Tensile Strength relations may vary according to the processing history or the chemical composition of the steel. This conversion calculator gives approximate hardness values for various hardness scales based on the Rockwell C Scale.

The basic Brinell hardness of manganese steel is 220 but that with impact wear the surface hardness will increase to higher than 550. American Piping offers this handy conversion calculator for converting the hardness measures of steel pipe using Brinell Rockwell and Tensile values. Medium Carbon Steel Composition of 029-054 carbon with 060-165 manganese.

205 400 58 HRC. While not as hard as higher-carbon steels carburizing can increase its surface hardness. We show carbon steel mechanical properties physical properties and more.

AISI 1018 carbon steel can be easily hot worked. The annealed state has good machinability low cold deformation plasticity and poor. Carbon Steel Sheet Types.

View carbon steel properties from E-Z LOK today. 65Mn steel is a Chinese GB standard spring steel grade Manganese Mn improves hardenability so the strength hardness elasticity and hardenability are higher than that of 65 steel but it has overheat sensitivity and temper brittleness. Figure Comparing Hardness Scales.

C Scale A Scale 15N Scale Superficial B Scale 30T Scale Superficial ksi MPa-66. Stainless Steel Round Bar 304304L Cold Finished. Brinell Hardness Number Carbide Ball Rockwell Hardness Numbers Tensile Strength.

Hardness Rockwell Brinell. In former standards HB or HBS were used to refer to measurements made with steel indenters. Low Carbon Steel Composition of 005-025 carbon and up to 04 manganese.

Average dew point 7 C 45 F. It is normally used in turned and polished or a cold drawn condition. It has high machinability high strength high ductility and good weldability.

STEEL HARDNESS CONVERSION Reference Table. Converted from Brinell hardness. Intermediate annealing has to be performed to overcome the alloys tendency to work harden.

Carbon Steel Round Bar Cold Finished. Temperature C F Rockwell hardness HRC. 1095 high carbon steel carbon content.

The Brinell hardness. The most common low-carbon structural steel in the world A36 Hot Roll Steel is strong heavy ductile and cheap. The Brinell hardness number is designated by the most commonly used test standards ASTM E10-142 and ISO 650612005 as HBW H from hardness B from brinell and W from the material of the indenter tungsten wolfram carbide.

High-carbon steel has approximately 060 to 100 carbon content. Normalized at 885 C 1625 F water quenched from 800-815 C 1475-1550 F. AISI 1020 has low hardenability properties and is a low tensile carbon steel with a Brinell hardness of 119 235 and a tensile strength of 410-790 MPa.

Conversion for Non-Austenitic Steel Table 1. 16 Conversion Table 6 presents data on the relationship. Hot and Cold Rolled 2mm4mm6mm8mm Thick Galvanized Carbon Steel SheetPlate Coil.

Converted from Brinell hardness. Brinell HardnessHB RockwellHRC RockwellHRB VickersHV Nmm² 800 72 780 71 760 70 752 69 745 68 746 67 735. Stainless Steel Round Bar 316316L Cold Finished.

As the content of Carbon increase the steel plate hardness increases. Hardness is higher than the other grades but ductility decreases. The accuracy of the conversion depends on the.

Water quenching tends to form cracks. Forging of AISI 1018 carbon steel can take place in the range of 996-1260C 1825-2300F.

A Yield Strength Tensile Strength And Brinell Hardness Versus Download Scientific Diagram

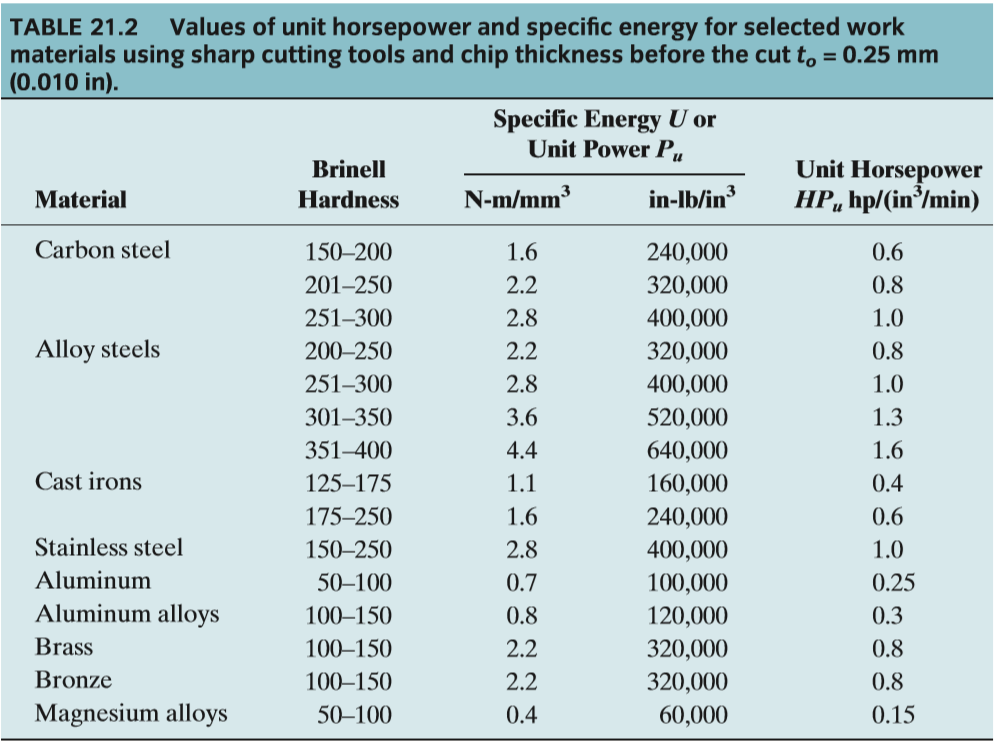

Solved 21 22 In A Turning Operation On Plain Carbon Steel Chegg Com

Suggested Screening Values Of Brinell Hardness Number Bhn For Download Table

Process Brinell Hardness And R Values Download Table

0 Response to "Carbon Steel Hardness Brinell"

Post a Comment